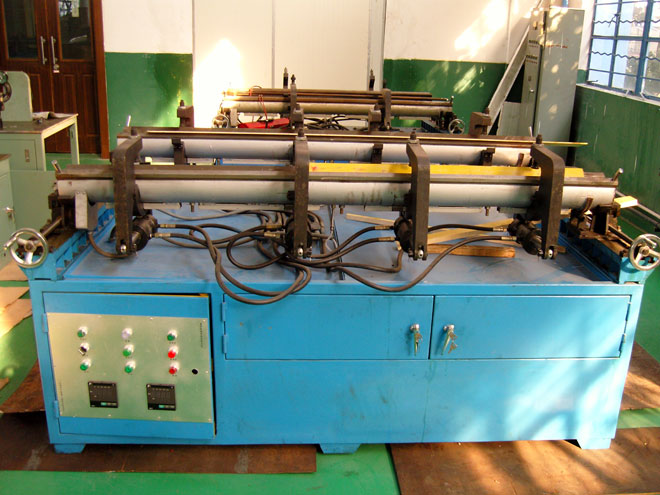

Semiautomatic Framework Coil Hot-press |

||

| Product Photos | ||

|

||

ZCN01-1200 Semiautomatic Framework Coil Hot-press (4 heads) Technical specifications: 1. Electric heating power 10kW, maximum temperature 2. Oil pressure 6MPa, 3.6 tons each edge (resultant force of 2 pressure heads working simultaneously); 3. Adopting the technology of automatic prepressurization (low pressure), automatically exerting full pressure after 5~10 minutes; 4. Opening of coil: 180~ 5. Maximum sectional area: 25 × 6. Length of mould: ZCN01-1200 Semiautomatic Framework Coil Hot-press (6 heads) Technical specifications: 1. Electric heating power 10kW, maximum temperature 2. Oil pressure 6MPa, 5.4 tons each edge (resultant force of 3 pressure heads working simultaneously); 3. Adopting the technology of automatic prepressurization (low pressure), automatically exerting full pressure after 5~10 minutes; 4. Opening of coil: 180~ 5. Maximum sectional area: 25 × 6. Length of mould: ZCN Technical specifications: 1. Electric heating power 12kW, maximum temperature 2. Oil pressure 6MPa, 6.9 tons each edge (resultant force of 3 pressure heads working simultaneously); 3. Adopting the technology of automatic prepressurization (low pressure), automatically exerting full pressure after 5~10 minutes; 4. Opening of coil: 190~ 5. Maximum sectional area: 32 × 6. Length of mould: ZCN Technical specifications: 1. Electric heating power 16kW, maximum temperature 2. Oil pressure 6MPa, 9.2 tons each edge (resultant force of 4 pressure heads working simultaneously); 3. Adopting the technology of automatic prepressurization (low pressure), automatically exerting full pressure after 5~10 minutes; 4. Opening of coil: 190~ 5. Maximum sectional area: 32 × 6. Length of mould: ZCN Technical specifications: 1. Electric heating power 20kW, maximum temperature 2. There are 5 pressure heads on each side, oil pressure 6MPa, 11.5 tons (resultant force of 5 pressure heads working simultaneously), operated by button; 3. Opening of coil: 230~ 4. Maximum sectional area: 32 × 5. During the mould pressure process, taking a prepressurization for 5~15 minutes, then automatically exerting pressure.

Considering the protection of our technical secrets, the technical drawings and parameters of the product are not issued on website, if you need to inquire more informations of this product, it is very precious of you to send e-mails to xxe@vip.163.com or leave your questions on our message board in "Contact Us". |