Kapton Taping Machine |

||||||||||||||||||||||||

| Product Photos | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

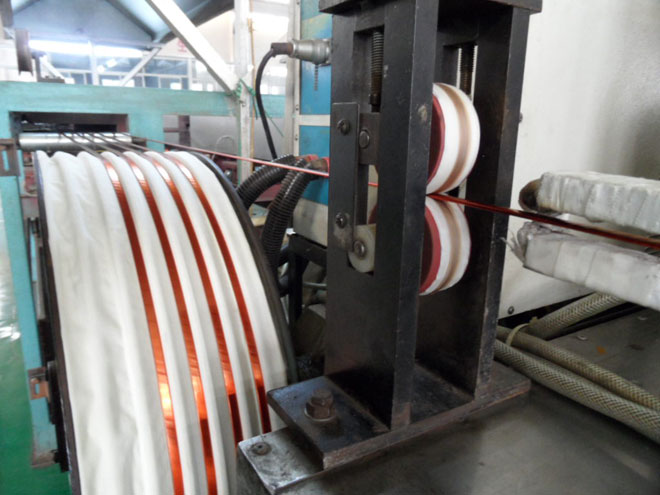

HORIZONTAL KAPTON TAPE INSULATING AND SINTERING/SEALING PLANT 1. General Description: This single production line is suitable to tape one or two layers of Kapton tape / Polyimide tape evenly, closely and continuously in opposite direction around copper conductor as per IS/BS (IS: 9148) specification. It is very similar to the Glass Fibre Covering Machine, but also includes an induction heater, two nipping rollers and a water quenching tank for product cooling resulting in the Kapton tape being firmly bonded with the bare conductor. 2. Technical Specifications: The Horizontal conductor taping and sintering machine for taping Kapton tapes to bare conductor consists of the following equipment and/or units: 1. Pay-off supply stand with disc brake 2. Wire straightening unit 3. Buffing unit with dust extraction 4. Taping Head 5. Caterpuller (Pedrail pressure roller) 6. Induction Heater 7. Two sets of Nip / Pressing rollers to avoid any air gap (Before and after oven) 8. Horisontal oven, open/closing type 9. Water quenching tank 10. Blower/dryer 11. Take-up unit 3. Short Description of Equipment and/or Units 3.1. Pay-off Unit The pay-off system shall be of the latest design, developed in order to effectively ensure quick loading and unloading of the supply drum by one worker and shall be fitted with adjustable disk brake tensioning device. The stand shall be suitable for drums up to 750mm in flange diameter. 3.2. Straightening and/or Tensioning Rollers The straightening rollers shall be manufactured from the latest design, chrome plated and there shall be 7 rollers mounted in horizontal plane and 7 rollers mounted in vertical plane. 3.3. Buffing Unit The buffing unit shall consist of two uni-directional motorized wire wheels and shall be enclosed and equipped with a dust extraction unit. 3.4. Taping Head The taping head shall be of the latest design, including the photo-electric induction paper tape breaking system as well as the servo control system for adjusting and precisely controlling the lapping pitch. 3.5. Cater puller The Cater puller shall be supplied for pulling of the strip before take-up unit complete in all respects. Cater puller shall have 600mm haul-off length approx. and the belts are made out of special rubber. It is driven by the transmission shaft through flexible coupling connected through the P.I.V and gearbox. The gearbox serves to drive the Cater puller to suit the wire/strip as well as changing the lapping percentage with the help of PIV. The speed shall be 0 to 4 meters. 3.6. Induction Heater The induction heater will be of the following specification: a) Radio frequency Induction Heater - 18KW b) DM water cooling system c) Work coil – 1 Nos. Approximate specification of RF induction heater: Rated Output : KW 18 Input Power : KVA 36 Power Supply : 380 Volts, 50 Hz 3.7. Nipping rollers These rollers shall be fitted before and after the curing oven and serve the purpose of eliminating air between the conductor and the kapton tape. 3.8. Horizontal Oven 15KW electrically heated oven with opening closing arrangement. Maximum temperature 500ºC. The length of the oven shall be approximately 3 meters and the width 1 to 2 meters. Power Supply : 380 Volts, 50 Hz 3.9. Water Quenching Unit The kapton covered material shall pass through a water quenching tank of appropriate size in order to cool down the conductor sufficiently before being wound on drums at the take-up. Preferebly the water shall be sprayed on and it may be necessary to include a heat exchanger. 3.10. Air Blower After being cooled down sufficiently, the covered conductor shall pass through this blower unit to dry the product. 3.11. Take-up unit The take-up unit shall be electrically driven and fitted with a torque motor.

Considering the protection of our technical secrets, the technical drawings and parameters of the product are not issued on website, if you need to inquire more informations of this product, it is very precious of you to send e-mails to xxe@vip.163.com or leave your questions on our message board in "Contact Us".

|